Plandt Biology Unit research topics

MIKROALGAE BIOTECHNOLOGY

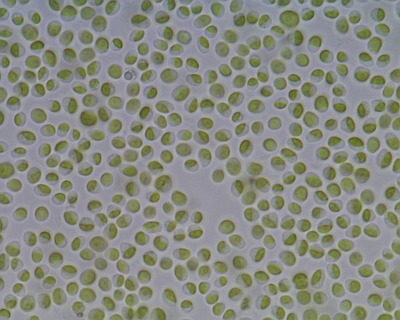

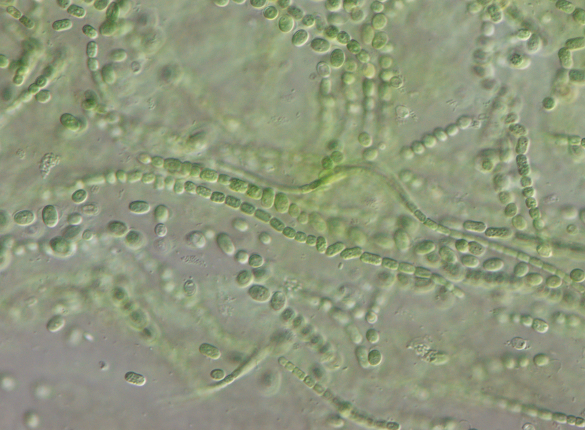

The term microalgae, as used in applied algae biotechnology, includes the various divisions of microscopic eukaryotic algae and the oxygen-producing photosynthetic bacteria, or cyanobacteria. Microalgae live mostly in water, but can also be found on the surface of different soil types. Compared to aquatic microalgae, soil algae live in a much more extreme and rapidly changing physical, chemical and biological environment. They respond to almost constant stress by adapting their metabolism or by producing bioactive substances, and are therefore more valuable for biotechnology than aquatic microalgae.

Microalgae, usually in the slow phase of reproduction, produce secondary metabolites, which are important biotechnological products. These include: organic acids, carbohydrates, amino acids and peptides, vitamins, growth regulators, antibiotics, enzymes and toxic compounds. Bioactive substances in algae have been the focus of interest for more than half a century. Today, they are the main potential feedstock for the pharmaceutical industry and agriculture. The decline in public acceptance of synthetic pesticides and pharmaceuticals has recently given a boost to research into active substances of natural origin, which is supported by the European Union.

Algae are valuable for agriculture mainly because of their plant growth regulating and plant protection properties. Microalgae biotechnology was given a new impetus in the 1980s by the idea of producing valuable materials and the development of closed algae cultivation facilities. The high price of polyunsaturated fatty acids (PUFAs), polysaccharides, antioxidants, natural colourants, biologically active substances, and raw materials for cosmetics, food and pharmaceuticals made the production of valuable materials by microalgae profitable, even at high investment and operating costs.

|

|

MOSONMAGYARÓVÁR ALGAL CULTURE COLLECTION (MACC)

The beginning of microalgae biotechnology dates back to 1890, when Beijerinck created the first bacteria-free (axenic) Chlorella culture using the microbiological methods in use at the time. Microalgae biotechnology refers to the culture of isolated microalgae as a strain culture or microalgalestrain. The mass isolation and maintenance of strains in algal collections was started by Pringsheim in the 1910s. The majority of algal collections in Europe consist of microalgae strains isolated from water.

The main goal of the Mosonmagyaróvár Algal Culture Collection (MACC) was to isolate the "more valuable" or perceived "valuable" algae. Between 1995 and 1997, the French company Thallia Pharmaceuticals provided substantial financial resources for the creation of a collection of algae strains, some of which were isolated in-house and others from hard-to-find collections. The MACC is the 15th largest microalgae collection in Europe and the 5th largest in terms of the number of soil microalgae. The MACC consists of nearly 1000 strains, including 600 species of soil algae. Of the 307 strains of Brazilian and 78 strains of Hungarian origin isolated, 50 are cyanobacteria and 385 are eukaryotic algae. We started to refine the taxonomic classification of the strains using molecular biology methods. Half of the collection (509 strains) is represented by 6 genera of importance for microalgae biotechnology: cyanobacteria Anabaena (82 strains) and Nostoc (57 strains), green algae Chlorella (122 strains), Scenedesmus (106 strains), Chlorococcum (72 strains) and Chlamydomonas (70 strains).

The microalgae strains of the collection have been used for several national and international projects over the last 25 years to study the production of plant hormones, antimicrobial activity and volatile organic compounds of microalgae for agricultural use, while the lipid production of microalgae as a renewable energy source has been studied.

PLANT BIOTECHNOLOGY

The Plant Biology Unit has been working on plant cell and tissue culture since 1986. Out of the nearly a thousand strains in the microalgae collection of the Department, dozens have been shown to have the potential to influence the growth and development of tissue culture plants due to their high production of hormones (auxin and/or cytokinin).

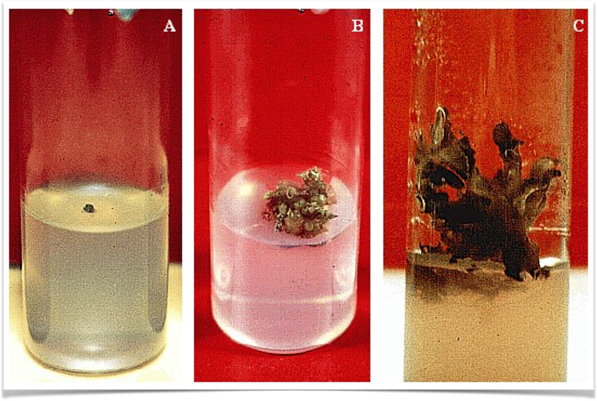

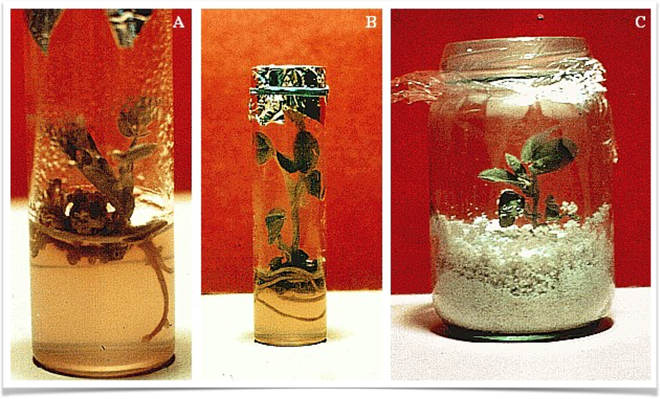

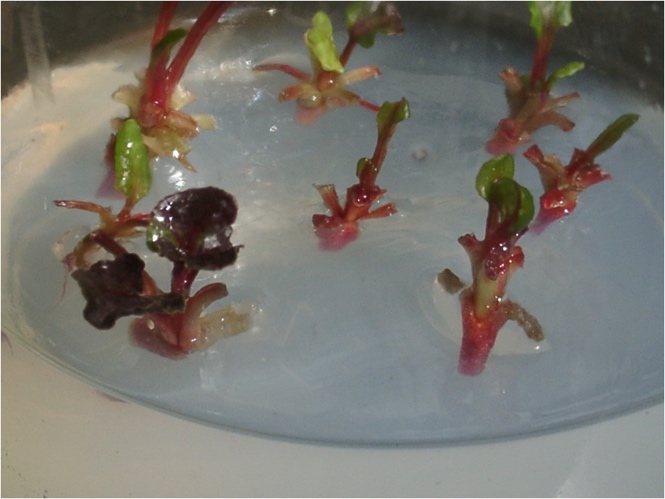

Our experimental results, supported by grant funding, have shown that extracellular products or biomass of microalgae, when added to the culture medium of tissue culture plants, promoted callus development of tobacco and pea, as well as shoot and root development. In recent years, it has been demonstrated in fodder beet that medium conditioned with a supernatant of microalgal suspension stimulated root development. Our aim in this field is to investigate further strains of the algal collection in cell and tissue culture of difficult to grow plant species.

Large-seeded legumes (faba bean, pea, fenugreek) are among the species that are difficult to grow in vitro (so-called recalcitrant). There is also a need to improve classical breeding methods for these crops through biotechnological applications. Our research objective is to initiate, maintain and possibly genetically modify in vitro tissue culture of the above-mentioned plants and different species of Beta vulgaris, and then to regenerate plants.

|

|

Our research topics:

- induction and maintenance of in vitro somatic cell and tissue culture,

- studying the effects of culture conditions, especially plant hormones, on previous cultures,

- study of the plant regeneration capacity of the cultures,

- genetic modification of pea and beet tissue cultures by direct gene transfer (gene grafting).

RESEARCH INFRASTRUCTURE

In the Plant Biology Unit's laboratory, the specialised laboratory instruments and equipment required for in vitro physiological, genetic, molecular biological and biotechnological work on microalgae and higher plants include:

- a seminar room equipped for 15-20 persons for plant biology exercises,

- laboratory equipped with the necessary tools for carrying out basic molecular biology work: PCR apparatus (Bio-Rad DNA Engine), PCR aspiration chamber (Bioquell Omni PCR), gel electrophoresis apparatus (Bio-Rad Midi), gel documentation apparatus with software (UVP BioDoc-It Imaging System), microcentrifuge (B. Braun A15), ice cream maker (Scotsman Frimont AF80), -80 °C freezer (National Lab ProfiMaster), all of them are also available for the ELKH-SZE PhatoPlant-Lab research team,

- two special rooms with a total floor area of 20 m2, air-conditioned and with controlled lighting for the propagation of microalgae and plant cell and tissue cultures,

- a dedicated culture room for microalgae strains (low light, temperature 16±1 °C),

- two greenhouses: 82 and 141 m2 , which are also used for the work of the other groups in the department,

- preparatory laboratories and equipment for the preparation and sterilisation of culture media for microalgae and plant cultures: balances, drying cabinets, dishwashers, water distillation apparatus, autoclaves, heat sterilisers,

- equipment for inoculating or starting up cultures: laminar boxes,

- genetic engineering device for in vitro genetic modification of plant tissue cultures (GENEBOOSTERTM),

- equipment for the examination, preparation, evaluation and storage of microalgae cultures and tissue cultures for bioassays: epifluorescence microscope (Olympus), refrigerated centrifuge (Sigma), freeze dryer (Christ), UV-VIS spectrophotometer (Varian), ultrasonic cell destroyer (Virtis), vacuum evaporator (Thermo Savant), refrigerators and ultra-low freezers,

- instruments for continuous monitoring of plant life parameters in field and greenhouse plant experiments: water potential and temperature probes and data logger/transmitter (Yara ZIM), chlorophyll content meter (SPAD), chlorophyll fluorescence meter (FluorPen, PolyPen PSI).

RESEARCH PROJECTS

Mikroalgae biotechnology

Over the last 20 years, the Plant Biology Unit has been approached by an increasing number of business representatives with three main topics:

- mass production of microalgae,

- cultivation of microalgae for biofuel production,

- microalgae for feed and crop management.

Some of the companies have given up their ideas in view of the difficulties, while others are in constant contact with us or have been in concrete research contact. Agro-Bioferment Ltd. in Budapest, Hungary, has provided technical advice on the licensing process of its microalgae formulation for crop treatment, while the company produces microalgae biomass for our research projects. In a joint research project with Phylaxia Pharma Rt, we investigated the beneficial effects of polyunsaturated fatty acids from microalgae on the composition of dairy products. With IC-Produkt ZRt. we researched high lipid microalgae for biofuel production. Among our domestic scientific contacts, we would like to highlight our continuous professional relationship with the research institutes of the former MTA (now ELKH), which in several cases means cooperation in joint research projects:

- ELKH ATK Agricultural Research Institute (Martonvásár): testing of natural algae preparations providing crop safety in organic production of sweet pepper, determination of the taxonomic location of microalgae by molecular biological methods, investigation of volatile organic compounds and insect repellent effects of microalgae.

- ELKH ÖK BLI (Tihany): microscopic taxonomic study of microalgae.

ELKH SZBK (Szeged): plant biotechnology techniques, molecular taxonomy of microalgae.

|

|

The research work of the Plant Biology Unit has always been characterised by internationality. International needs and trends have been taken into account when selecting our research topics. Research on algal biofuel production was initiated by a national contractor and continued with a previous TÁMOP grant. With financial support from the Land Brandenburg, we first worked together with the company Institut für Getreideverarbeitung GmbH in Nuthetal between 1993 and 1996. The production of plant hormone and the plant protection effect of algae were investigated by bioassays. Since 1995 we have been organising international scientific events together with the Institute. In one year we held a general European "Workshop" in Nuthetal covering all areas of algae biotechnology, in the other year we also focused on the agricultural and more recently energy use of microalgae at a "Symposium" in Mosonmagyaróvár. On behalf of the Hochschule Lausitz in Senftenberg, we participated in 2010 and 2011 in the project "Fixierung von Kohlendioxid aus Rauchgasen mittels Algen". In 2008, we started a collaboration with the Fraunhofer Institute for Interfacial Engineering and Biotechnology in Stuttgart in an EU-FP7 (FP7-SME-2007-2) project: "Development of an innovative industrial bioreacting and fermentation process producing an organic insect repellent-fertilizer for ecological farming". In the project, coordinated by Norway, we searched for and found insect repellent algae in the strains of the MACC collection. The successful collaboration resulted in another successful EU-FP7 (FP7-SME-2012) proposal "Development of a process to generate a novel plant protection product enriched with micronutrients to replace copper in organic farming". The aim of the project is to replace copper in organic viticulture. The Laboratory of Growth Regulators is jointly operated by Palacky University and the Institute of Experimental Botany in Olomouc, Czech Republic. We have a working relationship with the laboratory since 2002 on plant hormone production by microalgae. The Research Centre for Plant Growth and Development is a research centre of the University of KwaZulu-Natal (South Africa) in Pietermaritzburg, with whom we have been collaborating since 2001 on the study of hormone production in microalgae. Officially only a bilateral collaboration, we have involved the Czech laboratory in order to confirm our previous hormone studies using bioassays with instrumental analytical measurements.

|

|

Plant biotechnology

Between 2000 and 2002, with the support of the former OM Deputy State Secretariat for Research and Development, we succeeded in developing a generally applicable plant regeneration and transformation system (ref. BIO-00124/2000), which allows the rapid and efficient transformation of these difficult-to-cultivate plants (regeneration is genotype-dependent) with gene constructs carrying different traits of value for cultivation and processing. In our work, we investigated some parameters of direct (gene delivery) and indirect (Agrobacterium) gene transfer in a consortium with BETA Research Institute, Sopronhorpács, and the Agricultural Biotechnology Research Centre, Gödöllő.

Taking into account the results of the previous project, in 2005-2008 a new project (GVOP-3.1.1.-2004-05-0019/3.0, "Alternative energy source from Beta vulgaris L. by biotechnological methods") was carried out in the framework of a new call for proposals with the BETA Research Institute Kht., Sopronhorpács, in cooperation with colleagues, to produce fodder beet lines with higher sucrose content by reducing the endogenous Fru-2,6-P2 level for bioethanol production. After gene transfer, the transformed tissues were cultured on selective media and plants were regenerated from them according to the developed regeneration method. Putative transgenic plants were determined by PCR analysis, expression levels of useful genes by RT-PCR, and altered carbohydrate profiles by NAD - NADH interconversion enzymatic essays using spectrophotometry.

|

|

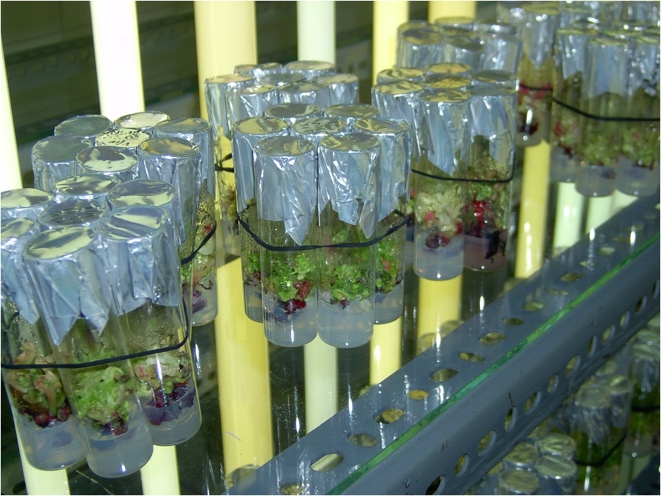

GOP-1.1.1-11-2012-0157 "Recovery of organic matter from suspensions with high lipid content and its industrial utilisation"

Our application was awarded a grant of HUF 585,190,340 by the decision of the Managing Authority of the Economic Development Operational Programme. The primary and immediate objective of the project is to develop energy-efficient new processes and new equipment prototypes for the market production of organic matter from suspensions with a high lipid content (algae suspensions, dairy wastewater, oil wastewater from the mechanical industry), so that the biomasses produced, which are sometimes classified as hazardous waste, can be used for industrial applications. The development will include the production of prototypes of equipment that can be developed into mass production equipment that is economically, technically, energetically and environmentally optimal, and the registration of patents for the new industrial processes and technologies developed. The long-term goal of SKC Consulting Limited Liability Company is to develop a flexible algae cultivation system that ensures near-maximum photosynthesis and production capacity, which can be adapted to the needs of the market, and from which the equipment can be used to produce economically harvestable raw material suitable for primary further processing. Reducing the wasteful use of potable water quality water in the dairy industry by purifying and reusing the effluent produced on site, and by-products of the purification process will also be recycled as organic biomass. On-site treatment of industrial waters contaminated with organic hydrocarbons, bringing pollutants below the limits required by law. Significantly reduce the level of industrial pollution through continuous monitoring by on-line remote monitoring for environmental and other authorities. consortium members.

TÁMOP-4.2.2.A-11/1/KONV-2012-0003 "Microalgae biotechnology in sustainable agriculture"

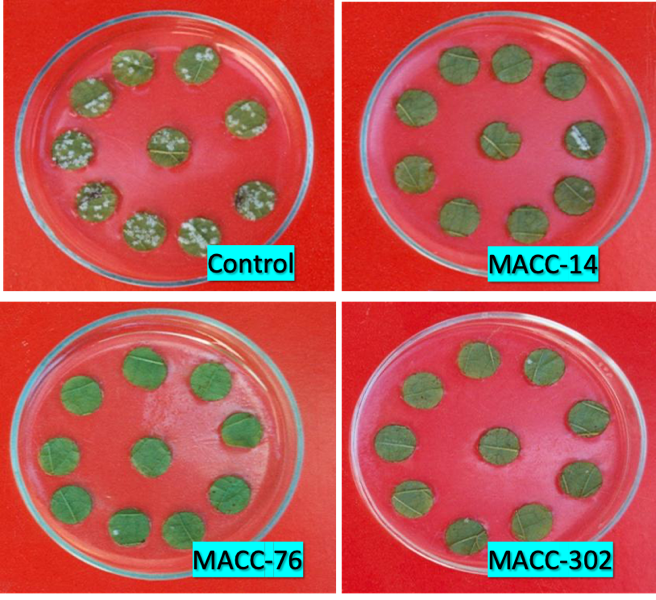

The project was supported by the European Union, co-financed by the European Social Fund, with a total amount of HUF 492,826,142. Today, humanity is facing two major challenges: global warming and the increasing price and insecurity of fossil energy. Microalgae biotechnology not only offers a solution to both challenges, but also has the potential to produce unique metabolic products that other organisms do not produce. The uptake of carbon dioxide by microalgae reduces emissions of this greenhouse gas while producing quantities of biomass and biofuels that no other photosynthetic organism can. However, this new biotechnological approach can only be successful if we improve the energy balance of the process and reduce the cost of producing algal biomass. Technological development must move towards the development of cheaper and lower operating cost algae cultivation equipment, which can make biofuel production economical. In addition, the special secondary metabolites produced by algae could be potential raw materials for the pharmaceutical and agricultural industries, which will require the development and application of new molecular biology methods. The decline in public acceptance of synthetic pesticides and pharmaceuticals has recently given a boost to research into active substances of natural origin, which is supported by the European Union. The research activities with 3 sub-projects and 10 topics were carried out in consortium (NymE Faculty of Agriculture and Food Sciences, Hungarian Academy of Sciences Agricultural Research Centre, Institute of Agriculture) over a period of 31 months, starting on 1 December 2012. In this project, we aimed to extend our achievements in biopesticide and biofuel research to an international level by developing and applying novel molecular biology methods. The key to improving the energy balance for the production of biodiesel from microalgae is the development of simpler and cheaper processes and the full exploitation of the valuable residual biomass to make it economically viable. In this project, we aimed at improving the energy balance by appropriate measurements. We also investigated the extent to which the production of valuable materials for agriculture in microalgae depends on the environmental conditions of their propagation and the extraction method of the algal biomass produced.

The Plant Biology Unit provided the project leader (Prof. Dr. Vince Ördög) and project manager (Dr. habil Molnár Zoltán). The Institute's staff participated in subproject 2 ("Characterization of microalgae producing secondary metabolites with plant protective effects using molecular biological methods").

TÁMOP-4.2.2.D-15/1/KONV-2015-0023 "CLIMATE ACTION - Complex analysis of climate change impacts, preparation of international R&D proposals at the University of West Hungary"

The project was implemented with the support of the European Union, co-financed by the European Social Fund, with a gross grant amount of HUF 287,064,552. The aim of the CLIMATE project was to establish interdisciplinary basic and targeted basic research teams that are suitable for participation in the European Union's research programmes, in particular Horizon 2020. In addition to the participation of researchers from the different disciplines of the University, as well as renowned foreign researchers, particular attention has been paid to the involvement of young researchers, doctoral students and undergraduates. The groups established on the basis of inter- and multidisciplinarity will significantly increase the R&D&I&O capacities of the University, ensuring qualitative and quantitative improvements in knowledge production and exploitation. In the course of the project, research has been carried out in a wide range of disciplines that directly or indirectly touch almost the entire spectrum of engineering, information technology, life and natural sciences. We are generating new scientific results through complex analysis of the impacts of climate change, adapting international R&D experience and testing new research methods. It will broaden the professional knowledge of those involved in research and strengthen the University's international research collaborations, which could trigger new international R&D projects. As climate change and climate change impact assessment is a priority area in the EU, the project could also provide a significant opportunity to join leading international research teams. The project will run for 8 months, with two consortium partners, the University of West Hungary and the Centre for Ecological Research of the Hungarian Academy of Sciences, starting on 2 April 2015. On behalf of the University of West Hungary, the research will involve staff from the Faculty of Forest Engineering, the Simonyi Károly Faculty of Technology, Wood Science and Art, the Faculty of Agriculture and Food Science, the Faculty of Science and Technology, the Faculty of Economics and the János Apáczai Csere János Faculty.

The Plant Biology Unit participated in the development of the sub-topic "B2) Increasing crop safety and pesticide-free crop protection - biotechnological application of microalgae in plant production and crop protection", under the leadership of Prof. Dr. Vince Ördög.

SABANA – „Sustainable Algae Biorefinery for Agriculture aNd Aquaculture”, No.: 727874

Duration: 01.12.2016 - 30.11.2020.

Funding: by European Union H2020-BG-2016-2017

Budget: 540,875.00 EUR (total: 8,848,523.75 EUR)

Project leader: for the departmental sub-project Prof. Dr. Vince Ördög.

The aim of the project is to develop a large-scale integrated microalgae-based biological purification system using only nutrients from seawater and run-off water (wastewater, pig slurry) to produce biostimulants, biopesticides and feed additives, as well as biofertilisers and fish feed. The end result will be the development of a demonstration system where the technology, operational parameters, environmental impacts can be evaluated and collaboration with potential users can be ensured.